Small-in-Window Air Conditioner Units Installation

Small-in-Window Air Conditioner Units Installation

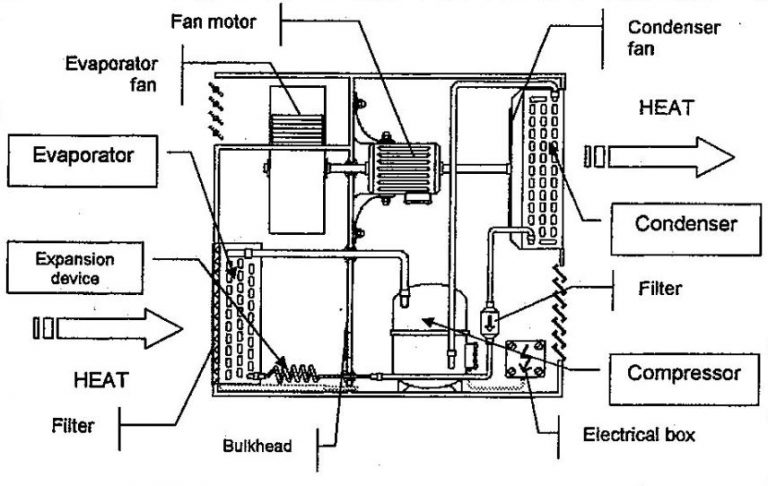

As its name suggests, unitary window air conditioners consist of a single item of equipment with compressors, evaporator, condenser, expansion device, fans and control within a common enclosure.

Formerly this design was widespread in use, but now it is slightly outdated. The typical installations are in a window space, hence its name, the window air conditioner.

You have almost certainly seen this type of window air conditioner installed above a hotel door, in windows, over shop doorways, in construction site offices, etc.

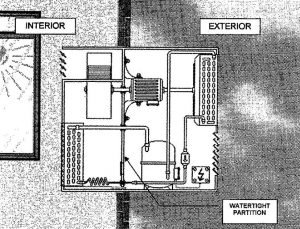

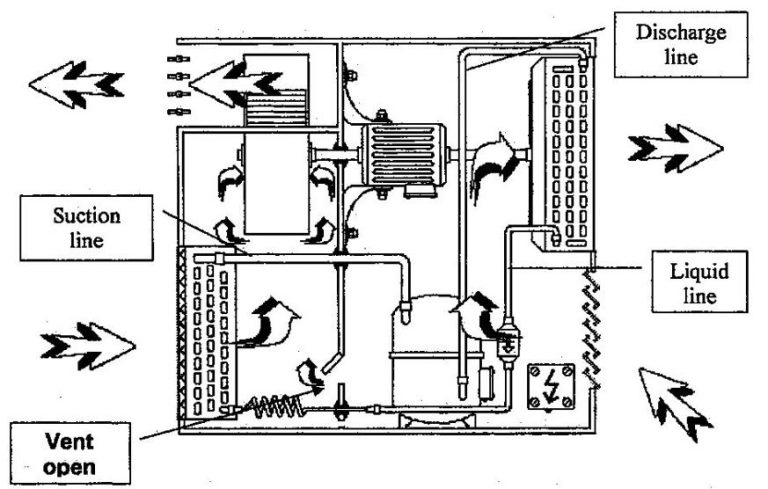

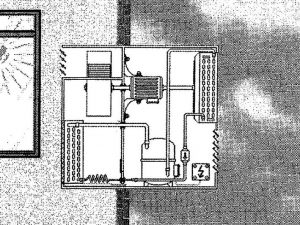

You’ll notice from the diagram below that one part of the unit is on the

interior of the room, whilst the other part is open to the exterior.

You’ll also observe that the interior part of the unit is separated from the

exterior part by a watertight (and airtight) partition or bulkhead. What do you think the purpose of this partition is?

A refrigeration circuit emits more heat from the condenser than it absorbs from the evaporator. So, the condenser must be placed outside the room if we want to cool a space.

As for the compressor, not only does it discharge heat, but it is also the noisiest element in the refrigeration circuit. Therefore, it would be better to place it on the outside to reduce the noise level inside the air-conditioned room as much as possible.

From the image, there are the filters, one refrigeration circuit, fans, a motor that turns the fans, and the bulkhead, which prevents any unwanted mixing of the air from the exterior with the interior air.

It’s important to understand that the bulkhead prevents any contact between the air on the interior and the exterior air.

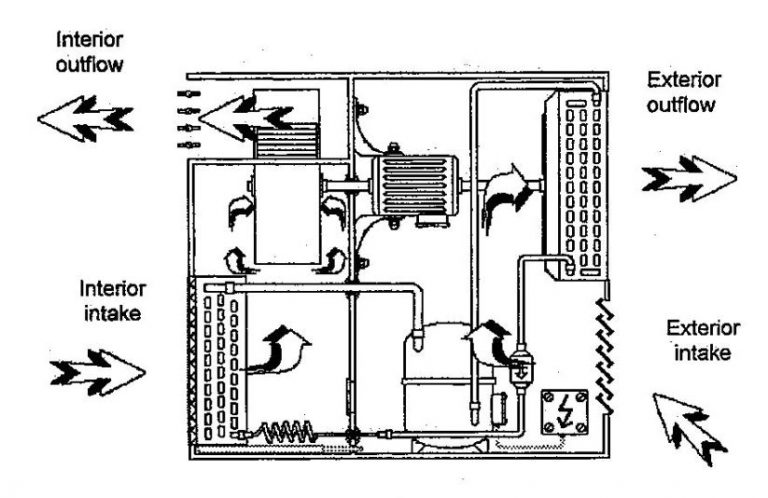

A window air conditioner unit is not a machine that takes external air, cools it and then discharges it into the room’s interior! Can you see how the air moves inside the unit?

It is essential to understand that window air conditioners have three different circuits: one refrigeration circuit and two separate circuits for the air. Let’s look at them in more detail.

Let’s start with the air in the room. First, the fan draws the room air through the filter and then over the evaporator. It leaves this heat exchanger having given up a part of its heat to the refrigerant. Next, the fan draws in this cold air and supplies it to the outflow grille. This first circuit causes the air in the room to cool by giving up its heat to the refrigerant, which then vaporises.

In the next stage, the compressor draws the vapour produced by the vaporisation of the refrigerant. After being compressed, it discharges in the form of hot HP vapour into the condenser.

Finally, the condenser fan draws the outside air across the condenser heat exchanger. Since the air is at a lower temperature than the refrigerant, it produces a thermal exchange, and the refrigerant gives up heat to the atmosphere. The air is therefore warmed up, and the refrigerant condenses.

The window air conditioners do not manufacture “cold”; they only pump heat from the room’s interior to discharge it outside.

Its operation is identical to that of a refrigerator. Hot air arrives at the evaporator and gives up its heat to the refrigerant, which then vaporises. The evaporator’s air supplies to the room at a temperature below ambient.

The compressor then draws the vaporised refrigerant via the suction line, compresses it, and discharges it via—the discharge line to the condenser.

Once at the condenser, the outside air cools the refrigerant, which causes it to condense. The outside air, which passes over the condenser, absorbs the heat of condensation and is then discharged at a temperature greater than ambient.

After condensation, the liquid refrigerant (at HP) travels to the expansion device (through tubing known as the liquid line). It then expands and enters the evaporator (at LP), absorbing more heat. This cycle repeats until it reaches room setpoint temperature.

Once we reach the desired room temperature, the window air conditioner thermostat stops the compressor and interrupts the refrigeration cycle.

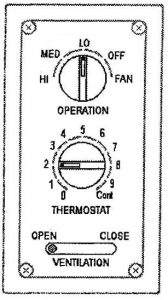

We can find the thermostat on the equipment, which is often the case for window air conditioner systems, or on a remote control unit.

On the opposite control panel, the thermostat control setting is in position 2. Of course, a setting of 2 doesn’t imply that the required temperature setting is 2°C, but it is only there to give the user some indication. The adjustment settings go from 0, the position where the compressor is never in operation, to “cont” (continuous), where the compressor is continually running.

There are some thermostats available with temperature setting scales graduated in degrees. However, we frequently find thermostats with window air conditioners that are very similar to the one shown in the sketch.

We’ll work on installing a control panel a little later, but for now, let’s look at the ventilation function on the panel. The selector can be in the ‘open’ or ‘closed’ position. You should note now that the selector does not control the operation of the fan motor.

In window air conditioners, allowing a little ‘fresh’ air from outside into the room you are trying to cool is possible. We do it using a small vent found on the separating bulkhead.

As you can see, when the vent is open a little way, air from outside can pass through the bulkhead. The air then mixes with the air from the evaporator. And drawn into the fan and blown out into the room. This fresh air supply means that the room’s air is gradually replaced, a bit like when we leave a window half-open.

What happens to the temperature of the air blowing into the room when we open this fresh air vent?

The cooled air mixes with this warm air, so there will be a rise in the interior airflow temperature.

Since the outside air is much warmer than the air cooled by the evaporator, the interior airflow temperature will rise. Therefore, if the window air conditioners are short of capacity to cool a room, it’s better to keep the vent open enough but not too wide.

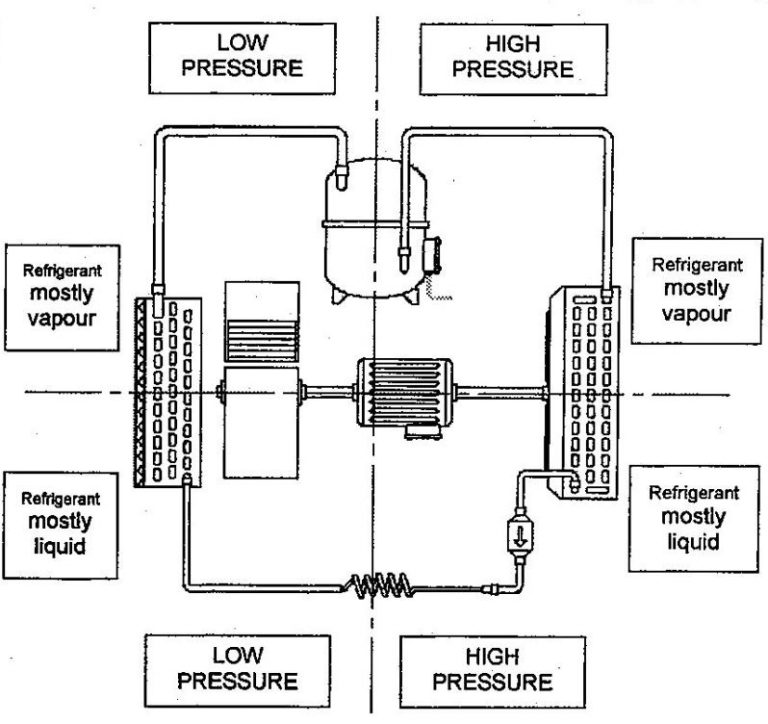

Although the technology of windows air conditioners is different from that of a traditional refrigerator, the operation of its refrigeration circuit is the same.

Just as with the refrigerator we saw earlier, we can break down the refrigeration circuit of an air conditioner into four main sections; LP, HP, primarily liquid and mostly vapour.

We can see that the greatest differences lie in the heat exchangers. They are different shapes, and they are both equipped with a fan.

The cooling capacity of air conditioning systems is much larger than that of refrigerators. In addition, in order not to have very large equipment, the thermal exchange is optimised by increasing the flow of air across the heat exchangers, which is the reason for the fans.

We must always remember that ‘comfort’ implies that the appearance of our systems must be acceptable. Therefore, the window air conditioners must be as compact and as discrete as possible.

We’ve already seen we do not consume refrigerant in the air conditioning systems. However, it is only strictly valid if we obey specific rules. For example, refrigerants cannot tolerate the presence of air, water or inappropriate oils. If we don’t follow these rules, there is a risk of the refrigerant decomposing to form dangerous acids that can rapidly destroy compressor motors!

The major advantage of a monobloc window air conditioner lies in the ability of the equipment to be assembled, tested and charged in the factory under near-ideal conditions.

Suppose we clean the filters and heat exchangers regularly. Then, the working life of a window air conditioner can be as long as that of a refrigerator, without any need for servicing the refrigeration circuit.

Unfortunately, window air conditioners possess two serious drawbacks. First, it is not attractive, and above all, it isn’t quiet.

Besides the fans’ noise, the compressor’s humming can transmit through the watertight bulkhead.

Nowadays, this type of equipment is common in temporary construction site offices or motorway toll booths where appearance and noise levels are not primary considerations.

However, in most cases, the noise produced by this sort of equipment is an important criterion. For example, imagine that a client has invested in air conditioning so that he can sleep when the nights are excessively hot.

OK, he’s no longer hot, but he can’t sleep because the equipment makes too much noise. What do you think his reaction would be?

The noise is produced by the fans and by the compressor. Therefore, to reduce the noise nuisance, we must place the noisy components and vibration sources at a distance from the room.

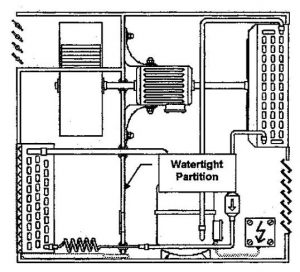

The partition in the middle of the equipment separates the interior and external air circulation. It is airtight but allows noise to pass through. in addition, compressor vibration transmits via the equipment chassis and refrigeration pipework.

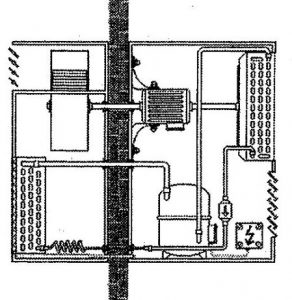

To improve our equipment, why not cut it in two where this partition is?

In this way, we could install the compressor and condenser fan on the other side of the wall, which would allow us to eliminate the best part of this noise nuisance.

Of course, the evaporator fan must remain inside the room, but this isn’t too much of a nuisance, as it’s the quietest element anyway.

To answer this question, what do you think of the set-up we installed below?

If we placed the compressor and the condenser fan on the other side of the wall, the air-conditioned room would be at a much-reduced noise level.

Does this system look OK to you? The refrigeration circuit shown would appear to be perfectly viable, and there is no reason why this set-up shouldn’t operate with a minimum of noise!

Have you thought about you are going to install this window air conditioner?

There is a danger of this design being fragile. The evaporator fan is, admittedly, situated in the room where we’re air conditioning, but the motor is on the exterior. And its shaft passes through the wall! At the time of construction, if we want the fans to rotate. We must ensure that the interior and exterior parts of the air conditioner are perfectly aligned. This design is not very practical!

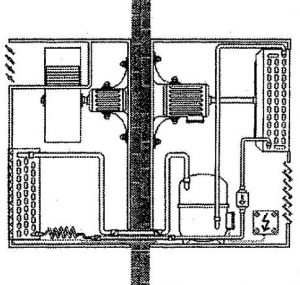

All we need to do is add a second motor to turn the evaporator fan if we want to eliminate this problem. We can then choose a low-noise fan motor assembly.

This modification has changed our original monobloc window air conditioner into a twin-bloc air conditioner.

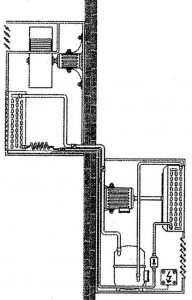

We will locate one part inside the air-conditioned room, holding the evaporator, fan, and motor. This part is known as the indoor unit.

We can locate the second part outside the air-conditioned room, which holds the condenser coil, fan, motor, and compressor. This part is known as the outdoor unit. We often call it the outdoor condensing set. Its function is to condense the refrigerant or, in short, the condenser.

You’ll observe in the image that we are splitting the air conditioning unit. We connect the two parts with refrigerant pipework. Hence we can install the outdoor unit in a different location and at different levels to the internal unit.

In this instance, our capillary expansion device is in the indoor unit, but in some cases, it is part of the outdoor unit.

For those air conditioner systems of modest refrigerating capacity (for example, those designed to air condition bedrooms), manufacturers often prefer to place the capillary in the external unit. In this way, the occupants don’t hear the whistling made by the capillary when the compressor starts and stops.

These are called split air conditioners.

Back to Basic!

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

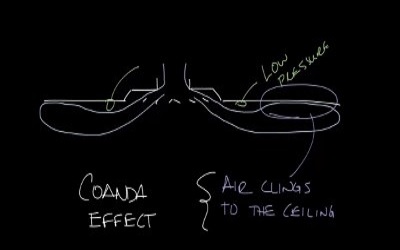

Read more: What is coanda effect