University of Adelaide Hub Central Indirect Air Conditioning

University of Adelaide Hub Central Indirect Air Conditioning

In 2011, we were tasked to resolve the HVAC system design for the University of Adelaide Hub Central. The solution was an custom built indirect evaporative cooling system. This central indirect evap plant is believed to be the most efficient evaporative cooling system in Australia.

Challenges

The original central chilled plant design was faced with some expensive remedial measures. For a start the chillers were too heavy for the roof; hence underpinning foundations and column/ beams reinforcement were required.

The second issue was the electrical consumption required for the chiller plant; an upgrade to the existing power supply with a new sub-station, but none was provisioned nor space for it.

University of Adelaide Design Brief in a nutshell

* 30% better than BCA

* design occupancy 800 people

* maximum outdoor air and natural light

* six food outlets

* 24 hours/ 7 days

I conceptualised and designed the 465kWr indirect cooling and heating plant, and led the design team to the successful implementation and commissioning of the project.

Heat Mass Cooling Plant Design Statistics

* indirect evaporative cooling with 100% outdoor air during cooling cycle

* 11 indirect cooling heat and mass exchangers c/w roof mounted working air discharge fans

* 20 electronically commutated plug fans (38,000L/s supply air and 30,000L/s working air)

* 6 heating coils for hydronic heating during winter

* energy efficiency ratio of more than 10

* more than 70% electrical cost saving compared to chilled water system.

* environmentally friendly R718 refrigerant (water)

* filtered outside air with F4 bag filters

Project Outcome and Direct Benefits

* capital cost saving compared to the original chilled water system

* eliminated upgrade cost for new sub-station

* eliminated upgrade cost for structure and underpinning of the foundations to the original 40-year-old building, none required as confirmed by structural engineers

* improved project schedule

– simpler overall plant design

– lightweight roof plant

* operating and maintenance Life Cycle Cost saving (AS/NZS 4536:1999), when compared to

– chilled water plant

– packaged air conditioning

– split packaged air conditioning

– variable refrigerant systems

The biggest benefit of the plant; was it did not contribute to the existing power supply problems we now faced across the country.

The design was subsequently commended for Innovation and Research Development by Engineers Australia, South Australia in 2012.

Seven years after commissioning, the cooling plant is still operating at an unprecedented energy efficiency ratio of more than 10, three to four times better than a comparable chilled water systems.

Suitable Application

* Factories with high internal sensible heat load

* Application where single pass air flow is required

* High air flow volume application such as clean rooms and data centres

* Shopping complexes

Limitation of the indirect evaporative coolers

* needs dehumidifiers for areas with high ambient moisture content

For more details or help in your designs, just shoot me a message through LinkedIn.

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

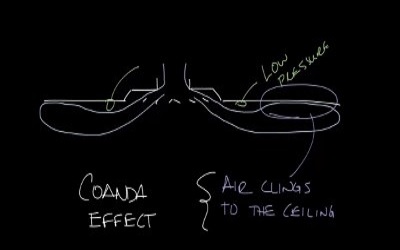

Read more: What is coanda effect