The Refrigerant Gauges

The Refrigerant Gauges

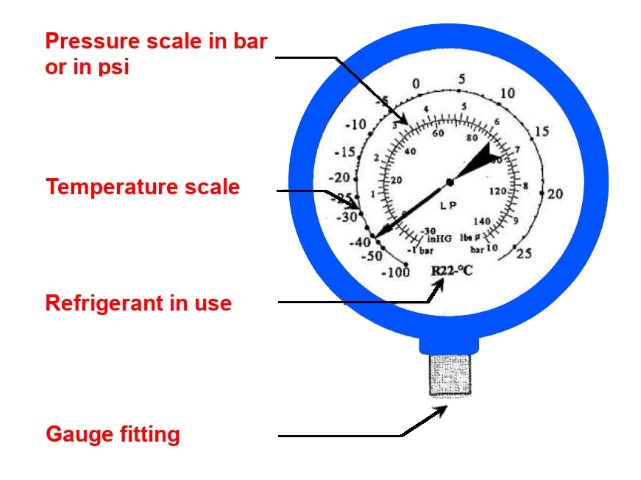

Let’s examine the refrigeration pressure gauge: this is the type of gauge used daily by fridgies.

- It has pressure connectors used to connect it to the refrigeration circuit via a special flexible hose.

- It has two pressure scales (we will use the bar scale) and a temperature scale. Note that the needle indicates 0 bar since the gauge is open to the atmosphere.

- It has scale refrigerant R22.

Before we continue, you should think about these two questions;

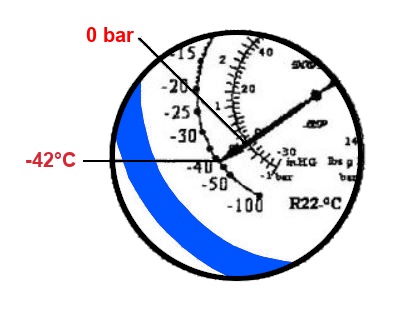

1. Why does the gauge read 0 bar when not connected to a fridge system?

2. Why does the needle indicates -42°C on the temperature scale when not connected to any system?

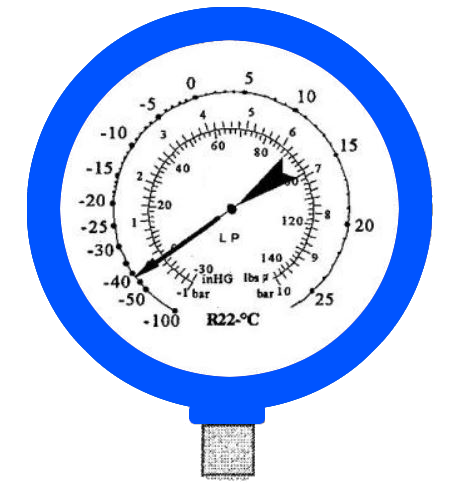

The pressure gauges measure atmospheric pressure as the pressure connection is open to the atmosphere. Remember that, by convention, all refrigeration gauges calibrate to 0 bar at atmospheric pressure. So the needle may indicate 0, but the pressure isn’t zero. So the gauge only compares the pressure it measures with atmospheric pressure.

The pressure shown on a gauge is called relative or gauge pressure. It is relative to the atmospheric pressure with a true value of 1.013 bar absolute. We’ll round this to a practical value of 1 bar.

Absolute Pressure = Gauge Pressure + Atmospheric Pressure (1 bar)

We express gauge pressure of 0 bar relative to the total vacuum, i.e. 0 + 1 = 1 bar.

So, if the gauge shows 4 bar (gauge pressure), the absolute pressure will be 4 + 1 = 5 bar.

All gauges show gauge pressure, but some technical information (that of refrigerant manufacturers, for example) will refer to absolute pressures. So exercise great care when you consult this type of literature if you want to avoid making mistakes.

We’ve just seen that a gauge that isn’t connected (open to the atmosphere) measures atmospheric pressure. Therefore this corresponds to 1 bar absolute, that is, 0 bar gauge. The needle, thus, shows 0 bar.

Remember that at atmospheric pressure (that is 0 bar on the gauge), liquid water evaporates at +100°C, liquid ether evaporates at +35°C and liquid R22 evaporates at -42°C.

Remember that at atmospheric pressure (that is 0 bar on the gauge), liquid water evaporates at +100°C, liquid ether evaporates at +35°C and liquid R22 evaporates at -42°C.

If the gauge is for ether, at 0 bar, the temperature scale would have shown +35°C.

Why is there a temperature scale on all the refrigeration pressure gauges?

On the refrigeration gauges, it is a simple matter for the manufacturer to add, opposite the pressure scale, a temperature scale allowing us to read the pressure-temperature relationship for any given refrigerant.

Because of this, every time a fridgy measures a pressure, he can easily read off the temperature for the corresponding change of physical state simultaneously. It is much easier than reading this value from a diagram!

However, it would be best if you had a gauge for every refrigerant.

There are dozens of different refrigerants, and it isn’t possible to show the pressure-temperature relationship for every refrigerant on the same gauge. They’d quickly become unreadable!

On many gauges, the manufacturers show three temperature scales, that is, three different refrigerants: this works well and makes things easier!

Does the temperature shown by the needle always correspond to the temperature of the refrigerant?

Firstly, this is only true if you read the refrigerant temperature on the correct scale. So, for example, if you measure pressure in an R22 system, you must read the temperature on the R22 scale and not on the scales for R12 or R502 (which are other refrigerants).

Secondly, it is correct to say that the temperature scales give you the pressure-temperature relationship of the fluid in use. However, don’t forget that this relationship only exists when a physical state changes.

Given what we have learned, we can only apply the refrigerant pressure-temperature relationship under certain conditions. First, we must be sure that the gauge measures the pressure corresponding to the evaporation stage during a refrigerant’s change from a liquid state to a gaseous state.

If the refrigerant isn’t changing state, that is, if it isn’t in the form of a liquid/ vapour mixture, the temperature that the needle shows won’t correspond at all to the actual temperature of the refrigerant.

The refrigeration gauge allows us to measure the gauge pressure of a refrigerant; in addition, next to the measured pressure, the gauge indicates the evaporation temperature for the refrigerant at this pressure.

What is the operating range of this gauge, and what are the minimum and maximum operating pressures?

If we look closely at the pressure scale in the bar, we’ll notice that the minimum pressure is -1 bar and that the maximum pressure is 10 bar.

Therefore, the operating range of this gauge is from -1 bar to 10 bar.

A pressure of -1 bar corresponds to a total vacuum. Consequently, it is the lowest pressure that can exist.

Similarly, We should not use this gauge to measure a pressure greater than 10 bar under any circumstances.

In practice, the fridgy uses two types of gauges, One to measure Low Pressures (the LP gauge as shown) and the other to measure High Pressures (the HP gauge graduated for pressures up to 30 bar). These two gauges are practically identical, and only their operating range differs.

To avoid any possible damage, before using any measuring devices, for example, not only for pressure but also voltage or current meters. You must check its operating range and establish the order of magnitude of values to be measured beforehand.

Back to Basic!

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

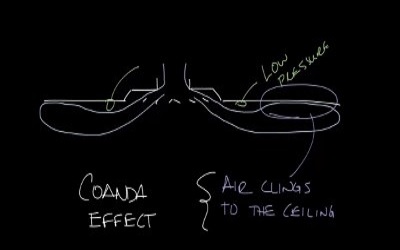

Read more: What is coanda effect