What is Thermal Expansion Valve (TXV) or Electronic Expansion Valves (EEV)

What is Thermal Expansion Valve (TX Valves) or Electronic Expansion Valves (EEV)

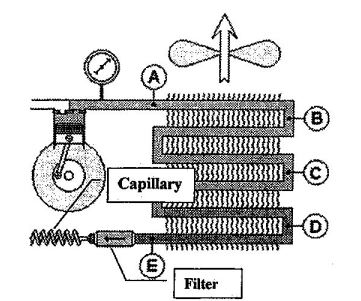

All air conditioning refrigeration circuits have expansion devices such as a “capillary” tube, thermal expansion valves (TX Valves) or electronic expansion valves (EEV).

Take the capillary tube expansion device. It is the length of the small-diameter copper tube. But this simple tubing has a precise flow of refrigerant throughout the system. Therefore, we should never modify its properties. Despite its small size, this expansion device is just as essential as the compressor, condenser or evaporator.

The capillary has the same role as a camping- gas stove valve. The size of the flame depends on the opening of the gas valve. That is to say, the resistance provided by this valve to the passage of butane from the cylinder.

If we open the valve more, the resistance will be lower. Then more gas passes, and the flame becomes larger.

The same thing happens with the garden hose. The more we open the nozzle, the smaller the resistance and the larger the water flow.

In a refrigeration system, we see the same type of effect happening.

The flow of liquid through the expansion device depends. Similarly, increased resistance of the capillary will reduce refrigerant flow.

As far as the capillary is concerned, the situation is the same. The flow of liquid refrigerant depends on the resistance it offers to the passage of the refrigerant. But in contrast to the nozzle of a garden hose, the capillary is not adjustable. Instead, it is simply a long and narrow piece of copper tubing.

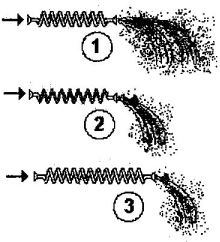

The resistance of the capillary depends on its diameter. Both capillaries 1 and 2 are the same length, but the diameter of 2 is much smaller. Since its resistance to the passage of refrigerant is greater, the flow through it is smaller.

The resistance of the capillary depends on its length. For example, capillaries 1 and 3 have the same diameter, but capillary 3 is much longer. Since its resistance to fluid passage is higher, its flow is lower.

When manufacturers install capillaries, they carefully establish the length and diameter required to produce a specific refrigerant flow. But be careful! If you have a problem, think that you can do something other than measure the length and diameter of a capillary to obtain an identical replacement!

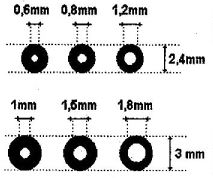

Anyone who has tried to measure the exact diameter of a capillary quickly realises that without specialist measuring equipment, all you can measure is the external diameter, and then often only approximately. Things then start to become complicated, as there are at least a dozen internal diameters between 0.66 and 2.29 mm available and dozen or more external diameters for capillaries from 1.83 up to 4.76 mm! And the complications involved don’t end here because there could be several possible internal diameters for the same external diameter!

You only have to leaf through the various refrigeration equipment distributors’ catalogues to see the many capillary tubing types available.

For example, an external diameter of 2.4 mm can have an internal diameter of 0.6 mm, 0.8 mm or 1.2 mm. Similarly, for an external diameter of 3 mm, there are capillaries with internal diameters of 1.0 mm. 1.5 mm or 1.8mm.

The lesson here is if you should ever need to replace a capillary, it’s better to buy a manufacturer’s original part. You’ll avoid a lot of trouble this way.

The internal diameter of a capillary tube is always very small (0.6 mm, for example). Therefore, it is the narrowest point in a refrigeration circuit.

Therefore, any contaminants that may be present (grit from abrasives, dust from brazing, etc.) are likely to obstruct the system. It could hinder or even block the flow of refrigerant and so prevent the operation of the air conditioning system.

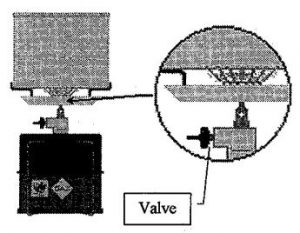

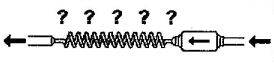

To prevent this, equipment manufacturers routinely install a filter before the inlet of the expansion device.

This way, any possible impurities remain trapped in the filter and won’t obstruct the capillary.

Note: filters typically have an arrow to show the refrigerant flow direction. Always install the filter the correct way.

Some filters have a double-ended arrow marked on them, as shown. Refrigerant can flow through these in both directions without causing any problems (this bi-directional filter is mostly for heat pumps).

But whatever their design, filters have another essential role. They all act in practice as filter-dryers.

Their second function then is to dehydrate the refrigerant, that is, to remove any moisture that may be present in the refrigeration circuit. Even in minute quantities, water is a refrigeration system’s No.1 enemy (and therefore yours too!)

Water and refrigerant can form powerful acids. These will cause oil to lose its lubricant properties and can attack the insulation lacquer on the electrical windings of the compressor motor. When this happens, motor burnout soon follows, as do numerous other problems.

But let’s get back to the capillary. We’ve seen that the refrigerant flow will depend on its length (the longer it is, the less refrigerant flows through it) and its internal diameter (the smaller its diameter, the less refrigerant flows through it).

Can you see another factor that could affect the flow?

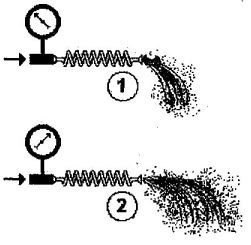

Let’s take two capillaries of precisely the same length and internal diameter.

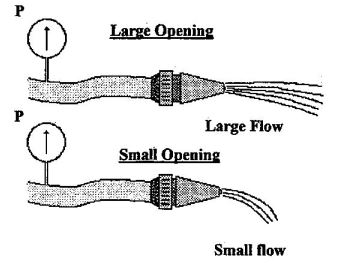

In case 1 opposite, the pressure at the inlet to the capillary is quite low. Therefore, the flow of refrigerant emerging from it is also low.

In case 2, the pressure at the inlet to the capillary is much greater. Since the force pushing the liquid through the tube is larger, it’s easy to see why the refrigerant flow is much greater than in the first case.

We’ve just observed a fundamental principle. Refrigerant flow also varies with the pressure at the capillary inlet. So, the refrigerant flow is a function of the pressure difference between the inlet and outlet of the capillary.

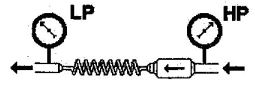

The refrigerant flow through the capillary depends, then, on the dimensions of the capillary used (its internal diameter and length). It also depends on the pressure difference between the inlet and the expansion device’s outlet, which is the difference between HP and LP.

Refrigerant flow and, therefore, cooling capacity depends on two factors, the dimensions of the expansion devices and the pressure difference between the inlet and outlet of the expansion device.

But do you know what determines the expansion device inlet and outlet pressures?

At the capillary inlet, the pressure is HP, and HP depends upon the air temperature at the condenser air inlet and ΔTtotal for the condenser (this is about 15 °C). How about the LP?

We should remind ourselves that selecting a capillary expansion device is a challenge. Nevertheless, we might have to replace one, for example, if it becomes blocked. If this happens, we can always unblock it first.

But where is the obstruction likely to be? If you don’t have a capillary cleaner (a manual pump that injects oil into the capillary at high pressure), you could blow nitrogen opposite the flow direction. You could shorten the capillary by a few centimetres on the inlet side. Note that the capillary depends on its length, and you should only shorten it a little).

Unfortunately, this doesn’t succeed very often, and you may have to change the capillary and the filter-dryer anyway (if the filter dryer had done its job correctly, the capillary wouldn’t block in any case).

Suppose you have a genuine replacement capillary supplied by the manufacturer of the faulty equipment and the same model as the blocked capillary. In that case, replacement is a relatively simple operation.

Remember that if you try to fabricate a replacement capillary yourself, it can often result in a series of problems.

The best solution is to note the exact details of the equipment in question and order the appropriate capillary from your refrigeration equipment supplier.

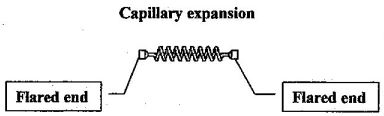

In addition, capillary expansion devices purchased from the manufacturer have two flared ends. These make fitting easier and eliminate any tube blocking due to brazing.

The expansion of a refrigerant is exactly the opposite of the compression of R22. The refrigerant heats up during compression. During expansion, it cools.

The length and diameter specified by the manufacturer cause a specific pressure difference across the capillary.

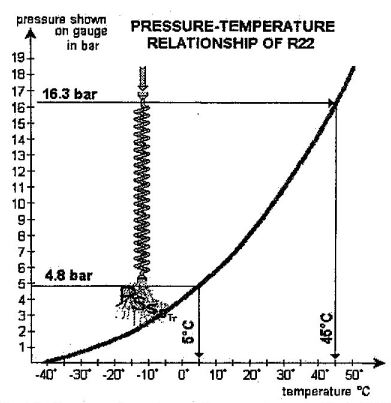

For example, a pressure of 16.3 bar at the inlet might fall to 4.8 bar at the outlet.

Since the pressure is only 4.8 bar, is the refrigerant liquid at 5°C, as shown by the pressure-temperature relationship for R22?

We must remove heat when we want to cool the liquid R22 from 45°C to 5°C. That’s why close to 20% of the liquid refrigerant vapourises as it passes through the expansion device. The heat lost by vapourising this 20% of the liquid refrigerant will cause the refrigerant temperature to drop as it passes through the capillary.

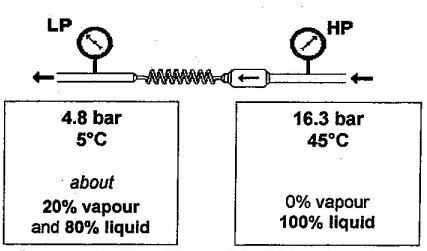

In summary, the capillary expansion device is a type of ‘lift’ that allows the refrigerant to descend from the HP to the LP level. The refrigerant enters the capillary as HP sub-cooled liquid and emerges as an LP mixture of about 20% vapour and 80% liquid.

So the pressure drop causes part of the liquid refrigerant to evaporate.

The liquid uses its own heat to evaporate, and this causes it to cool. But, if you think about it, the refrigerant wouldn’t cool from 45°C to 5°C just by magic, would it?

If the air temperature at the condenser or evaporator inlet changes, the LP and HP will also change. These changes mean that the refrigerant flow and, therefore, the refrigerating capacity of the equipment will change.

To avoid these sorts of problems, we must observe the restrictions in operating conditions laid down by the manufacturer. If we do this, we can prevent invalidating the manufacturer’s guarantee.

Back to Basic!

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

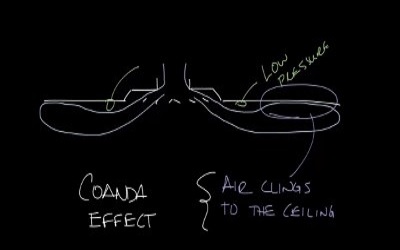

Read more: What is coanda effect