Commercial Kitchen Ventilation Designs

Commercial Kitchen Ventilation Designs

Among the frequent questions about designing commercial kitchen ventilation systems are sizing kitchen hoods exhaust and supply air flow rates, kitchen hood designs, fan control strategies, mitigating grease in ductwork, pollution control units and fire protection. In Australia, its requirements are dictated by AS/NZS1668.1 Section 6 and AS1668.2 Section 3. However, there are other standards overseas, such as the International Mechanical Code (IMC), which may be similar in many ways.

AS1668.1 Section 6

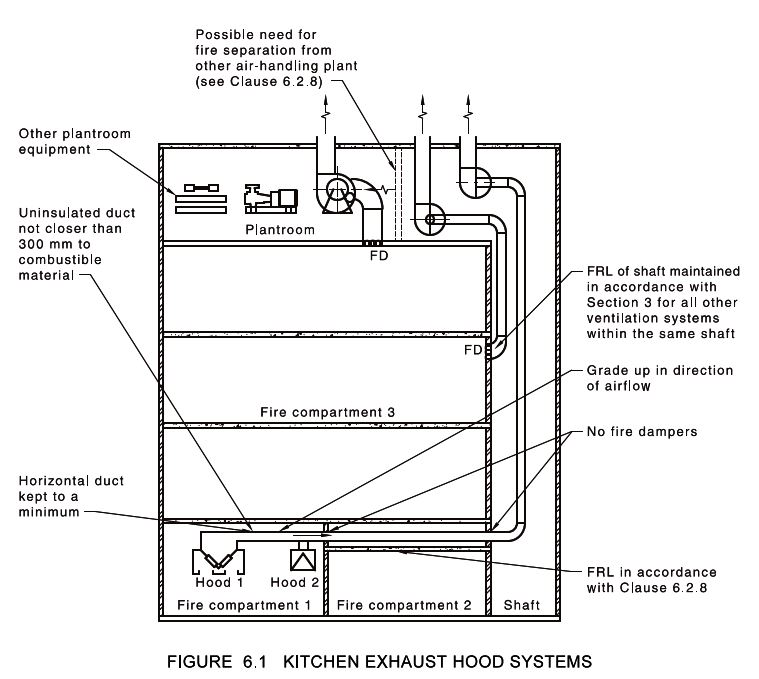

Where the kitchen exhaust hood systems are used to assist smoke control, the kitchen exhaust systems must not serve more than one fire compartment.

Kitchen exhaust ducts serving two different fire compartments must not share the same shaft.

All minor supply and exhaust ducts sharing a shaft with the kitchen exhaust ducts must have fire dampers when penetrating the shaft walls. It is to maintain compartmentation as fire may spread between the ducts.

Kitchen exhaust ducts must be at least 1.2mm thick galvanised steel or not less than 0.9mm thick stainless steel when not enclosed in dedicated fire-resistance shaft required by the National Construction Code and -/60/60.

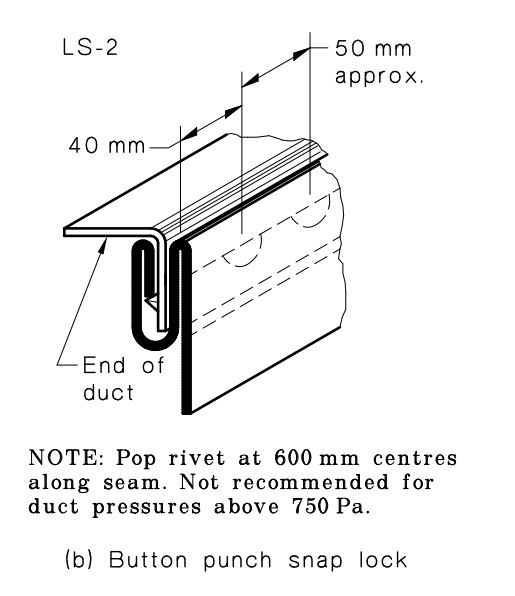

Button punch snap-lock joints must not be used.

Kitchen exhaust ducts when installed horizontally shall have a rise of not less than 5% in the direction of air flow. As much as possible install kitchen exhaust duct vertically. At each change of direction in the horizontal runs ducts access panel must be provided at every 3m.

A drain must be provided at the lowest point of each run of ducting.

Kitchen exhaust ducts must not be closer than 300mm (12 inches) to any combustible materials or to insulate to achieve -/30/30 FRL.

Kitchen exhaust ducts penetrating floors, walls, ceiling/ floor or ceiling/ roof into another compartment must be enclosed in fire-resisting constructions as fire damper are not allowed in kitchen exhaust systems.

Operation during fire mode

The kitchen exhaust fans must continue to run during fire mode, the supply air fans may stop if the supply air adversely affect the smoke layer. When the adjoining space to kitchen is within the same compartment, the kitchen exhaust system may be used for smoke control. As the kitchen will be under negative pressure.

A warning label as below must be installed at the kitchen exhaust system.

When the air handling plant for the kitchen is not within the same compartment as the kitchen, it must be enclosed within and FRL to maintain compartment integrity. Where other plant serving other compartments, all associated ducts must also be in fire-resisting constructions.

If the length of the exhaust duct exceed 10m and exposed flame or ember is part of the cooking process, UL1046 UL Standard for Safety Grease Filters for Exhaust Ducts must be provided.

Wood fired ovens or similar that produces sparks must be provided with spark arrestors at the connection to the duct.

AS1668.2 Section 3.4

This section of the AS1668.2 and Appendix E spell out the requirements for the seven most common types and configuration of kitchen hoods.

Hood Types

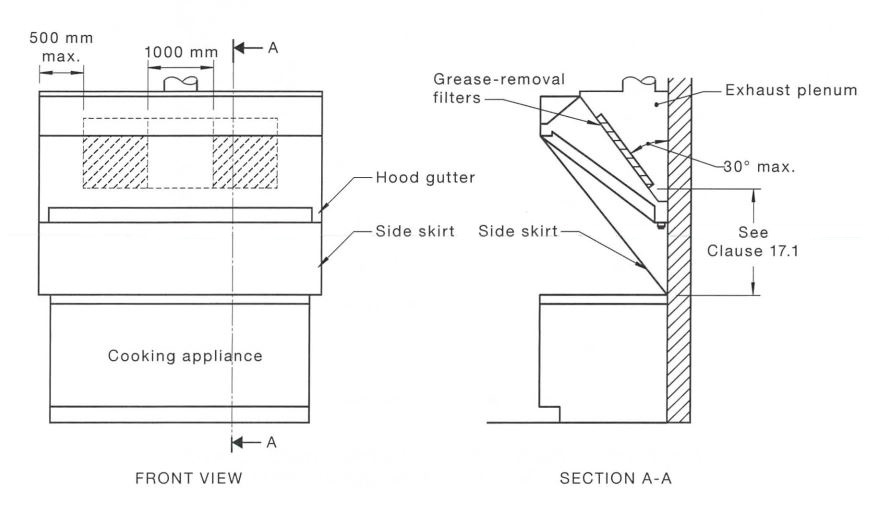

(a) Hood Type 1 Low sidewall where the canopy does not extend at least 150 mm beyond the edge of the cooking surface (see Figure E3, Appendix E).

(b) Hood Type 2 Corner-mounted, subject to a maximum length to width ratio of 2:1 (see Figure E4, Appendix E).

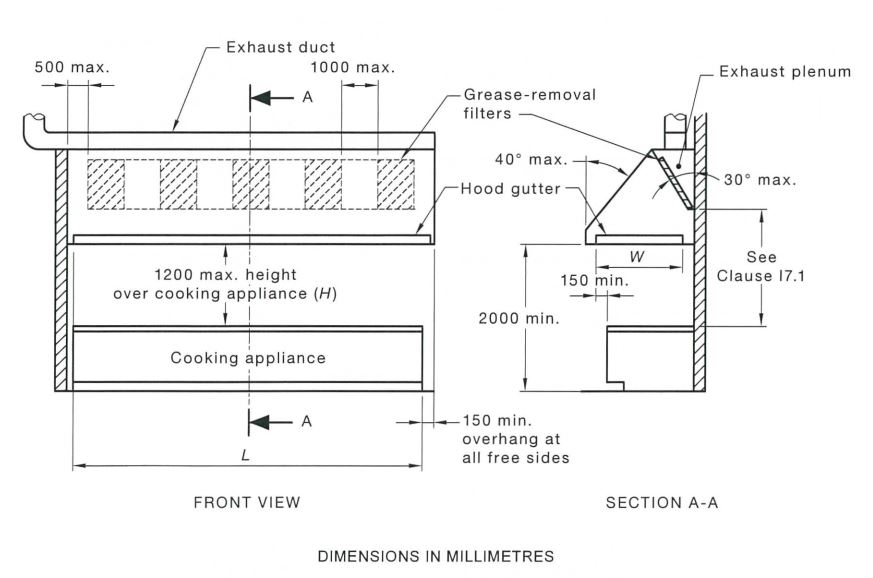

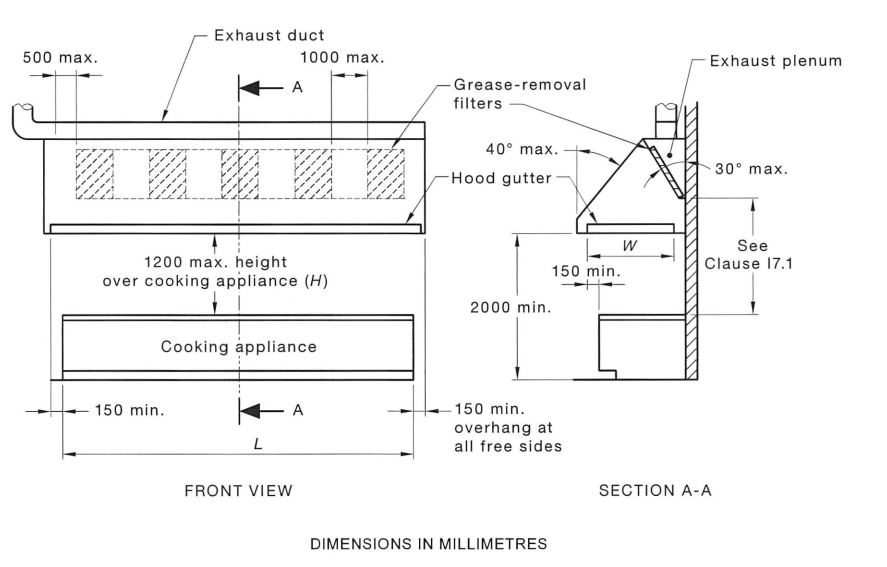

(c) Hood Type 3 Sidewall (see Figure E5, Appendix E).

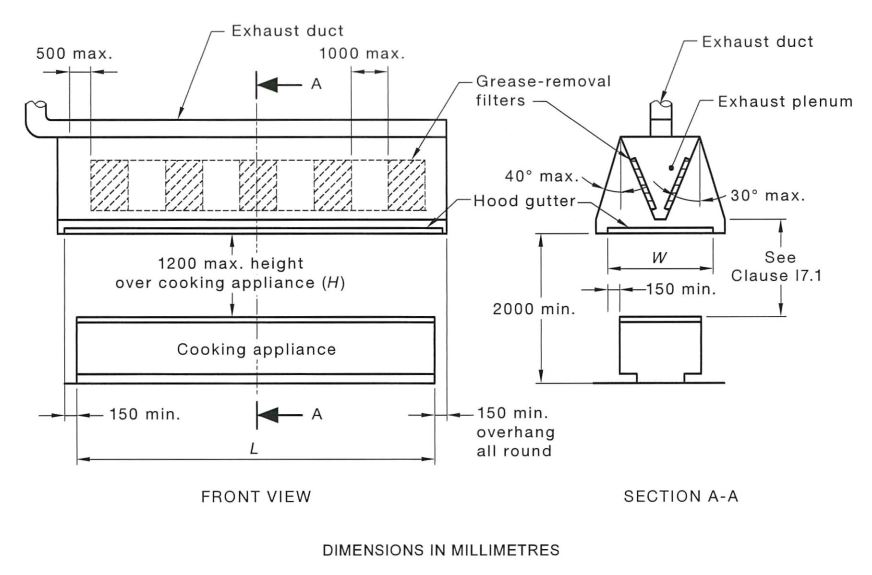

(d) Hood Type 4 Island (see Figure E6, Appendix E).

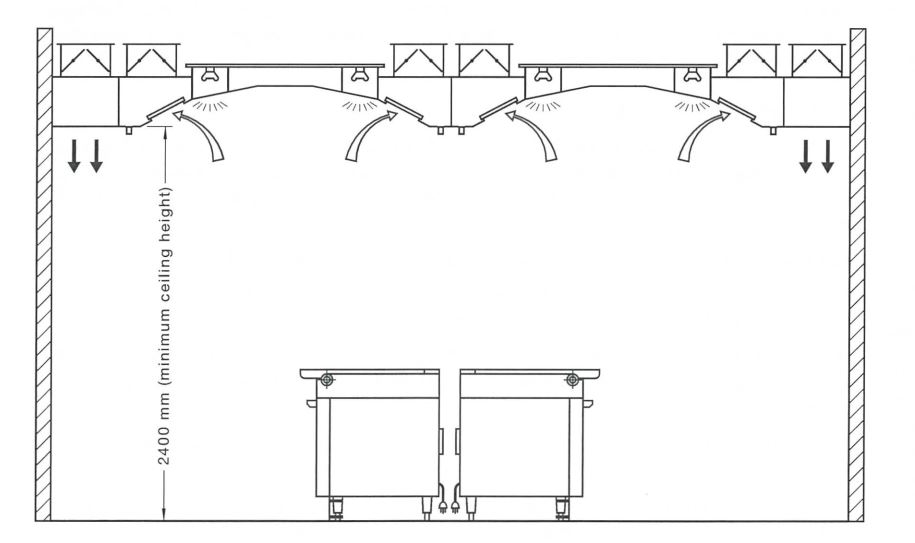

(e) Hood Type 5 Ventilated ceiling (see Figure E12, Appendix E).

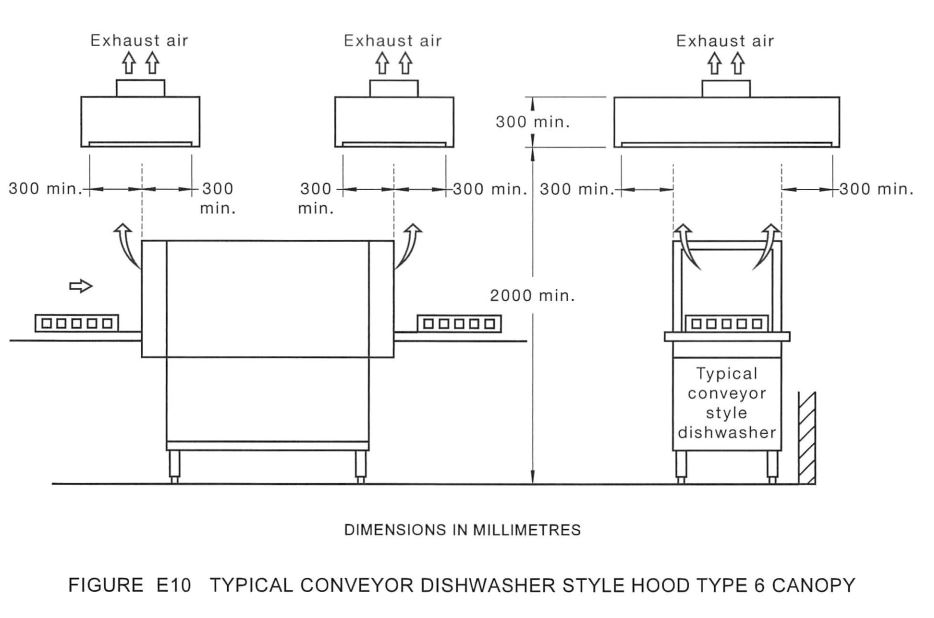

(f) Hood Type 6 Dishwasher Style hood (see Figure E10, Appendix E).

(g) Hood Type 7 Proprietary equipment.

Cooking process type

Kitchen hood over non-grease producing equipment

If the equipment does not product grease such as dish-washers, then grease filters are not required but the exhaust face velocity of the kitchen hood must be more than 0.3m/s.

If an overhangs on all sides of at least 300mm with minimum height of 300mm and contained hood volume no less than 0.3m3, then the face velocity may be reduced to no less than 0.1m/s.

Charcoal and solid fuel appliances

Charcoal and solid fuel appliance can not share the same hood with grease or oil-generating appliances. The exhaust from charcoal and solid fuel appliances, its exhaust will need to be treated to reduce contaminants. It must be kept below the max limit specified by the local councils.

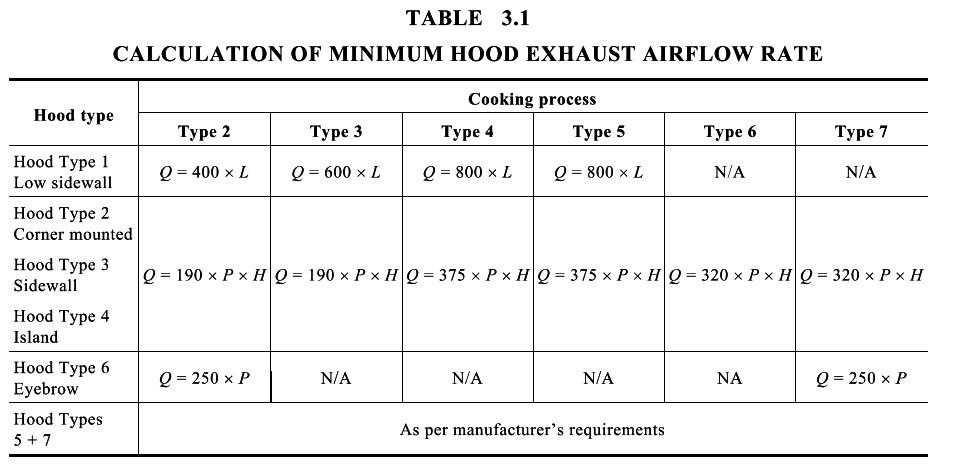

Kitchen exhaust air flow rates (Q)

When calculating the hood exhaust flow rate required, we will need to take the worst case application to determine the total airflow rate needed. Say, we have a Type 4 coking process under the same hood as a Type 2 cooking process, we will need to base our calculation on the Type 4 cooking process.

Under no circumstances that the exhaust airflow rate be less than 250L/s/m2 of cooking surface.

The calculation in the table below are based on the minimum overhand distance noted.

The hood overhand for Type 1 to 4 cooking process must not be less than 150mm.

Type 5 cooking process must not be less than 300mm overhang.

Type 6 and 7 cooking processes must not be less than 450mm overhang.

Under no circumstance that the length of the cooking appliances be more than the kitchen hood length.

Q = exhaust airflow rate, in litres per second

L = inside length of hood, in metres

W = inside width of hood, in metres

P = inside perimeter of hood over all exposed sides, in metres

H = height of hood above cooking appliance, in metres

Calculation of inside perimeter (P)

Hood Type 2 Corner mounted P = W + L

Hood Type 3 Sidewall P = 2 W + L

Hood Type 4 Island P = 2 W + 2L

Hood Type 6 Eyebrow P = 2 W + 2L

Requirements

Secondly, hoods need to install with an 450mm (18 inches) clearance to combustibles. We’re all familiar with the code requirement that grease ductwork requires an 18-inch clearance to combustibles, or we need to wrap it with insulation or fire wrap. We need to look at the hood as an extension of that grease ductwork if there are any combustible material within 450mm (18 inches) of the hood in all direction, including wood stud walls.

Some manufacturers can take exception to the requirements due to their hood designs and testing, so when it goes through the listing and testing, as you see in red on this chart, the airflow rates may be significantly lower than what the code requires. When designing and installing a kitchen ventilation system, some hood manufacturers will allow you to make exceptions to the code. They have recommended exhaust airflow charts, which you can use. These values are in cfm per linear foot of hood.

The most common question regarding untempered air is the international mechanical code requires that all makeup air systems start and operate automatically with the exhaust fan. We can accomplish that with heat detectors and control panel.

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

Read more: What is coanda effect