Microbial Induced Corrosion (MIC) in Pipes

Microbial Induced Corrosion (MIC) in Pipes

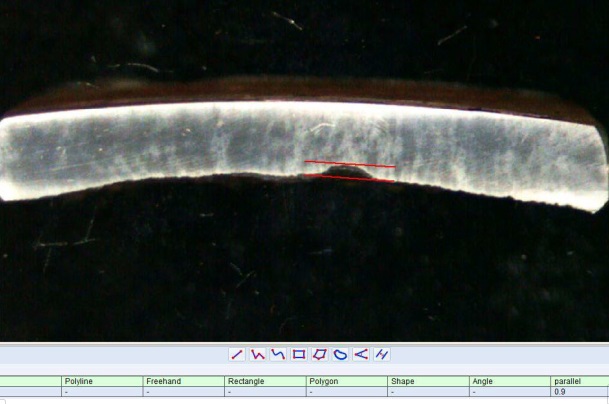

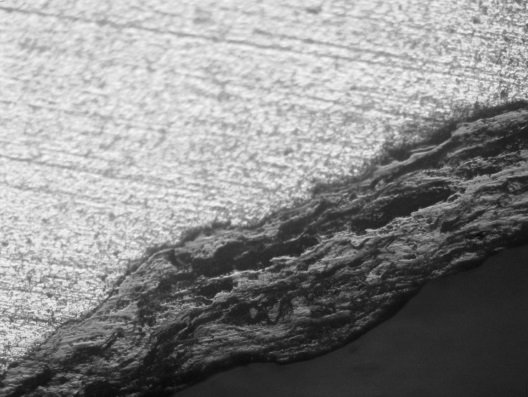

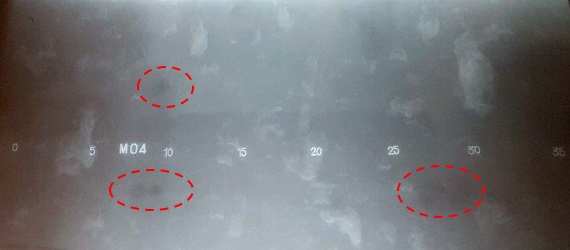

Thick layer of biofilm more likely a combination of calcium, iron oxide and microorganism on the top layer.

Thick layer of biofilm more likely a combination of calcium, iron oxide and microorganism on the top layer.

A black localized layer was observed, a product of sulphate reducing bacteria; bacteria reaction and iron sulfide corrosion products.

Corrosion here was not severe, and pitting are not aggressive yet.

They lacked in any significant depth; however, there was still potential for this to develop and become more severe.

All effective corrosion controls requires cleaning and passivation of the pipe reticulate then maintaining the appropriate alkalinity with maintenance dosage of chemical corrosion inhibitors and biocides. When the initial cleaning is not carried out appropriately, it will compromise the passivation that protects the base metal, the overall effectiveness of the initial high dosage of inhibitors at start up will be compromised. It is because the chemical corrosion inhibitors will not be able to forms a complete protective film on the metal surfaces. It will then be more likely to allow microorganism induced corrosion to develop in the years that follows; even with the recommended dosage of corrosion inhibitors, scale inhibitors and biocides during the monthly maintenance.

How to mitigate and reduce MIC in existing pipeworks

What is MIC

MIC or microorganisms induced corrosion is due to heterotrophic microorganisms such as sulfide reducing bacteria (SRB), iron reducing bacteria (IRB) and acid producing bacteria (APB) in the water. MIC is metal deterioration as a result of the metabolic activity of various microorganisms. This type of corrosion applies to non-metallic objects as well as metals. Microbiologically influenced corrosion has previously been referred to as biological corrosion and microbial corrosion.

SRB are commonly considered the main culprits associated with anaerobic MIC due to the wide availability of sulfate (SO42−) in the aquatic environment. SRB’s are those bacteria that can live by oxidizing organic compounds or molecular hydrogen (H2) while reducing sulfate (SO42−) to hydrogen sulfide (H2S). In a sense, these bacteria breathe sulfate rather than oxygen in a form of anaerobic respiration. SRB’s, or their characteristic corrosion product FeS, are ubiquitously found on anaerobically corroded steel.

Biofilm and deposits also increase friction resistance against the water which leads to increase energy consumption to operate the circulating pumps. These biofilms also protect underlying bacteria from biocides and biocide treatment. It is important to remember, when the biocide is become depleted and biofilm is removed, the system will become re-contaminated from the bacteria in the system. So the next step should be the bacterial removal process. It is important to re-test after the corrective action is carried out and then every few years to ensure the effectiveness of the chemical treatment and presence of bacteria in the water.

It is also important to review the maintenance program with the water treatment specialists and schedule specially the actions required when there is no circulation of water. When there is no water circulation, there is more chance of MIC formation. SRB, IRB and APBs can be detected by water analysis.

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

Read more: What is coanda effect