What do you want from your BMS. Part 3: Direct Expansion Evaporator Coils

What do you want from your BMS. Part 3: Direct Expansion Evaporator Coils

Follow the link below to read part 1 that first appeared on LinkedIn:

Part 1: What do you want from your BMS?

Let’s now look at the direct expansion evaporator when regular operation.

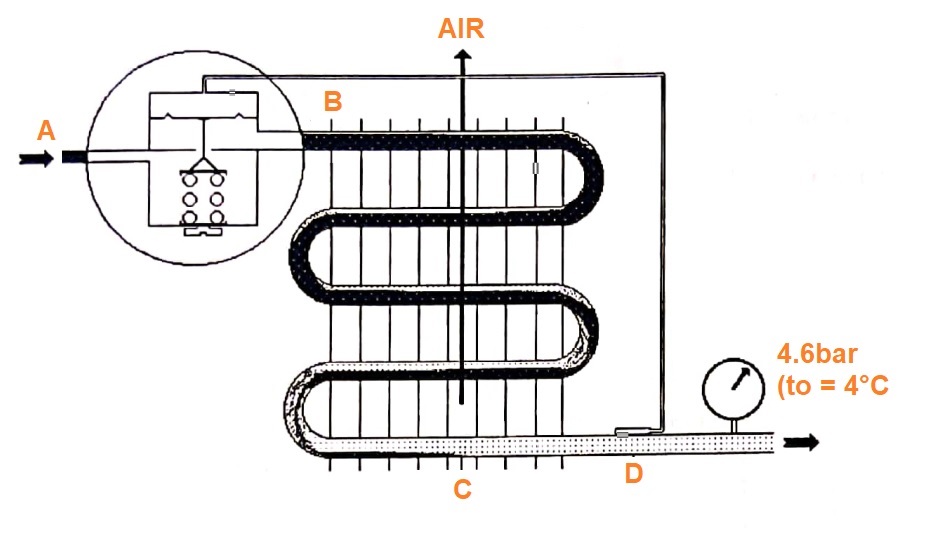

Point A: The liquid R22 vapour, at a pressure of 14 bar and sub-cooled to about 32°C, reaches the expansion valve.

Point B: The liquid expands as it passes through the calibrated orifice of the expansion device. The pressure dropped to about 4.6 bar after the expansion device. A part of the liquid has evaporated and cooled the entire vapour/ liquid mixture to about 4°C. At Point B, there is a mixture of about 20% vapour and 80% liquid; at a pressure of 4.6 bar and a temperature of 4°C.

Between B and C: The vapour/ liquid moves through the evaporator absorbing heat. There is more and more vapour present and less and less liquid as the refrigerant travels in the evaporator. The pressure and temperature are constant at 4.6 bar and 4°C, per the pressure-temperature relationship of R22.

Point C: The last molecule of liquid vapourises at 4.6 bar and 4°C. At this point, there is 100% gas at 4°C.

Between C and D: Since the vapour is in constant contact with air to be cooled, it’s temperature rises as it passes the evaporator along C-D. The pressure remained at 4.6 bar, but the vapour temperature increases.

Point D: The temperature at the expansion bulb is, say 11°C. The gas is, therefore, superheated by 7K between C and D.

Now let’s take a look at what happened at the airside:

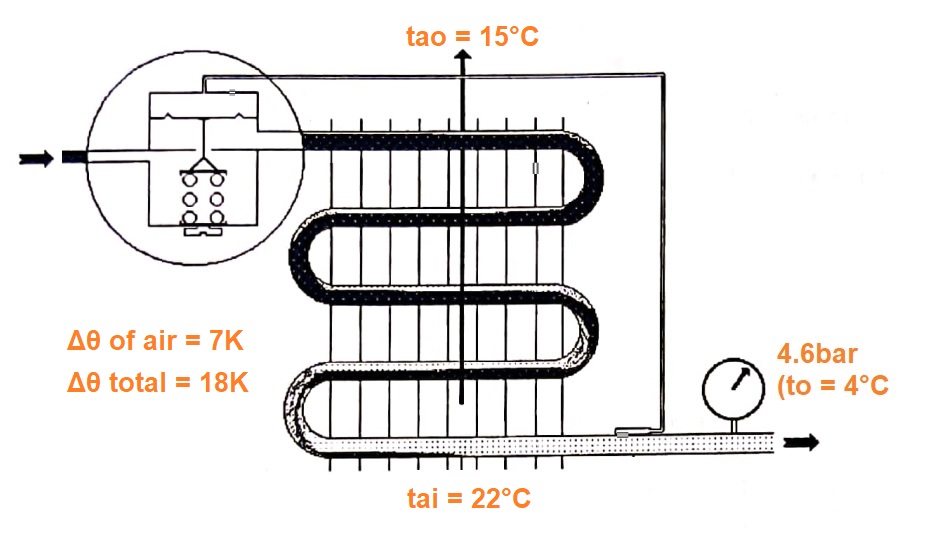

tai: temperature of the air at the evaporator inlet

tao: temperature of the air at the evaporator outlet

to: evaporation temperature, as read on the LP gauge.

In this example, the air arrives at the evaporator at 22°C and is cooled to 15°C as it gives up heat to the refrigerant.

Δθ for the air is (tao – tai) = 22°C -15°C = 7K

Also the evaporation pressure is 4.6 bar which has an equivalent evaporation temperature of 4°C for R22.

Hence Δθ total = (tai – to) = 22°C – 4°C = 18K

It is difficult to state normal values for Δθ for an evaporator because of the problems associated with dehumidification in air conditioning and with icing in refrigeration.

However; use the below as a guide, which is coil performance-dependent characteristic.

In air conditioning

Δθ for air (tai – tao) is about 6 to 10K and Δθ total (tai – to) is about 16 to 20K.

In commercial refrigeration

Δθ for air is 3 to 5K and Δθ total is 6 to 10K.

For condition monitoring, we can still make use of the Δθ for air and Δθ total trend log to give us an indication of coil performance over time, and remember it’s the anomalies that are important on these trend logs. In addition to the extensive use of variable speed drive fans and electronically commutated (EC) fans, we may also add the performance characteristic of the fans into our arsenal to enhance our condition monitoring capabilities.

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

Read more: What is coanda effect