What is Condenser in Air Conditioning Systems (HVAC)

What is Condenser in Air Conditioning Systems (HVAC)

The air-cooled condenser is a heat exchanger. What is the function of the condenser in an air conditioning system?

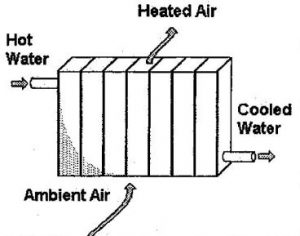

Do you remember the principle of operation of the central heating radiator? This heat exchanger allows us to warm the air in a room by exchanging heat between the hot water flowing inside it and the colder air on its exterior.

This thermal exchange is only possible if the water and the air are at different temperatures.

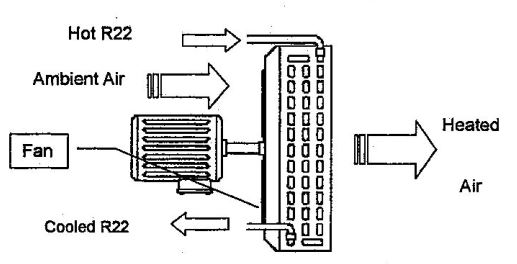

The operation of the condenser is the same. However, heat exchange occurs because the refrigerant (R22) and the air are at different temperatures.

As with the radiator’s air and water, the refrigerant and air exchange heat, the major difference is that the condenser has a fan in an air conditioning system to encourage heat exchange.

The condenser behaves like a radiator, except that instead of water, we use refrigerant!

Let’s look more closely at the condenser, concentrating on the direction of the flow of the refrigerant and the air.

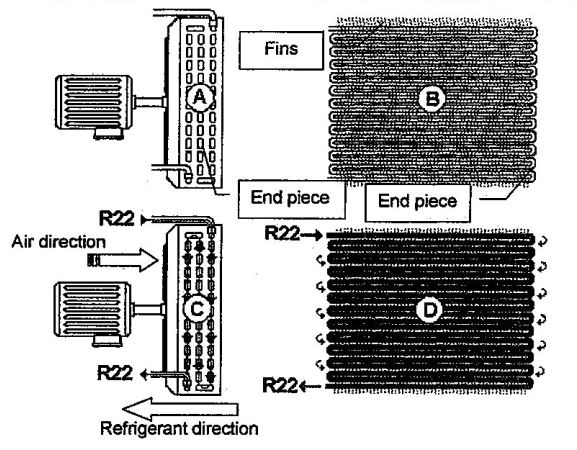

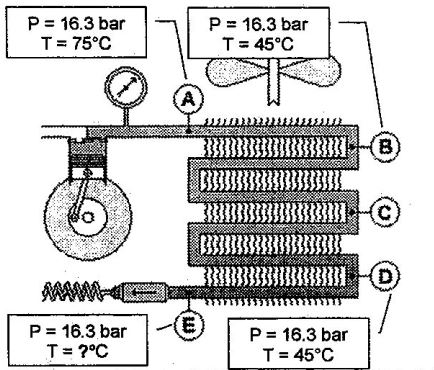

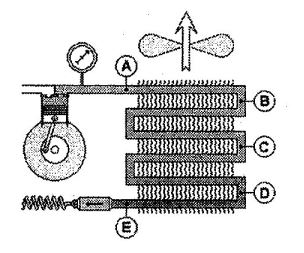

When you view the condenser and its fan from the side at A, you see two pipes, one connected at the top of the condenser and one at the bottom.

At B, you can see the condenser face-on. You can distinguish the fins (which increase the exchange surface) and the end pieces, which connect the horizontal tubes at either end of the heat exchanger.

At C, the R22 enters the condenser via the top right-hand pipe, which emerges from the bottom left-hand pipe, whilst the air flows from the left towards the right. The refrigerant and air, therefore, flow in opposite directions.

We say that the refrigerant and the air are in counter-current flow. This type of flow improves the effectiveness of the heat exchange between the two fluids. You should note that if the air and the R22 flow in the same direction, the flow is said to be concurrent.

A counter-current heat exchange is preferable as it allows us to obtain the same cooling capacity with a smaller heat exchanger. This way, we can reduce the bulk and cost of the equipment.

In D, you can see the refrigerant flow in the heat exchanger viewed face-on. The hot vapour that arrives at the condenser from the compressor outlet enters at the top and then condenses. Since the liquid refrigerant is heavier than the vapour, it collects at the bottom of the condenser.

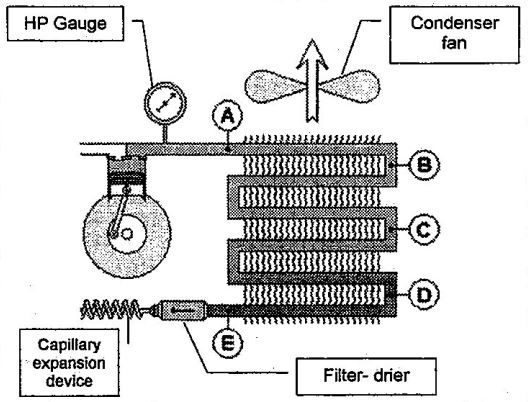

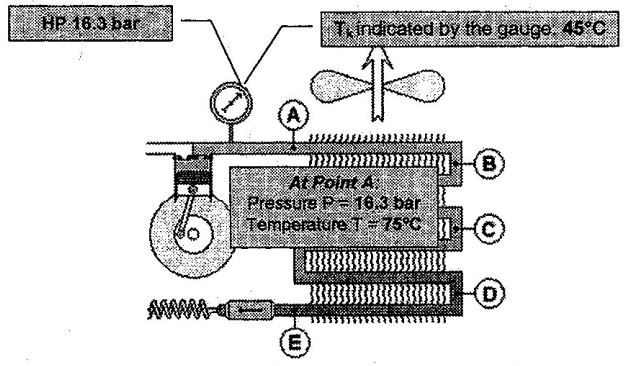

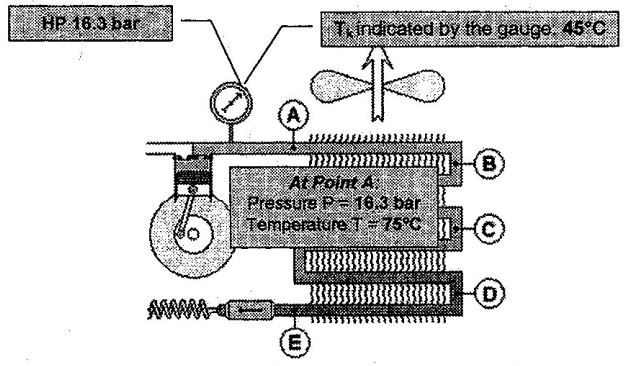

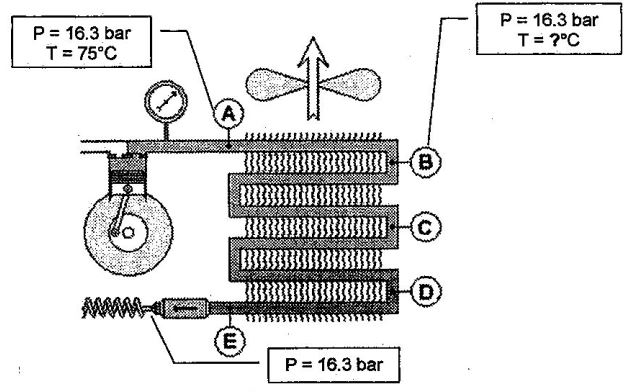

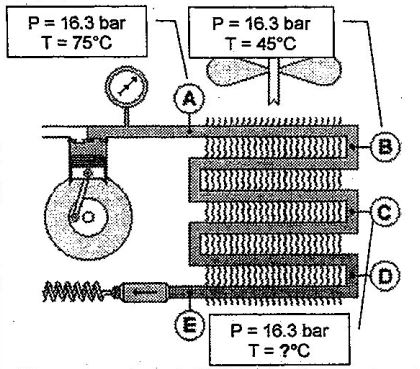

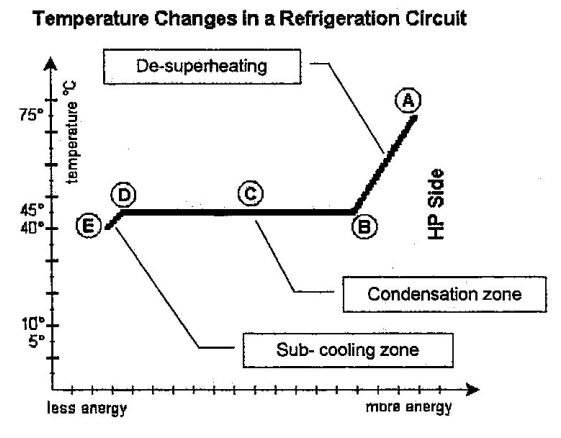

With the help of the diagram, we’ll see more closely the changes in the refrigerant as it passes through the condenser from point A to E.

Point A: R22 vapour arrives from the compressor at a high temperature and high pressure (HP).

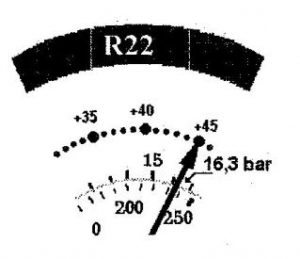

For example, imagine a high-pressure reading of 16.3 bar indicated on the HP gauge.

For example, imagine a high-pressure reading of 16.3 bar indicated on the HP gauge.

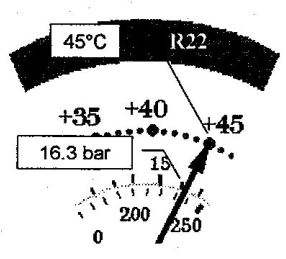

It indicates that the pressure on the HP side is 16.3 bar. But what does the temperature indicated on the gauge mean? Note that we refer to this as an indicated temperature and not as a temperature measured by the gauge.

In actual fact, a pressure gauge is a device that measures pressure and pressure only. It is not capable of measuring temperatures. We can only say that the refrigeration gauge can indicate a temperature. We need to understand just what this indicated temperature means.

What do you think the indicated temperature on the gauge refers to? For example, the temperature indicated on the gauge is 45°C.

Yet if we measure the refrigerant temperature at the compressor outlet, a thermometer reading would give a much higher temperature, say 75°C.

So, a gauge connected to the compressor discharge pipework adequately measures the discharge pressure, but all the evidence suggests that it cannot measure the temperature of the refrigerant in the pipe; if it could, it would read 75°C and not 45°C!

What does the 45°C reading correspond to?

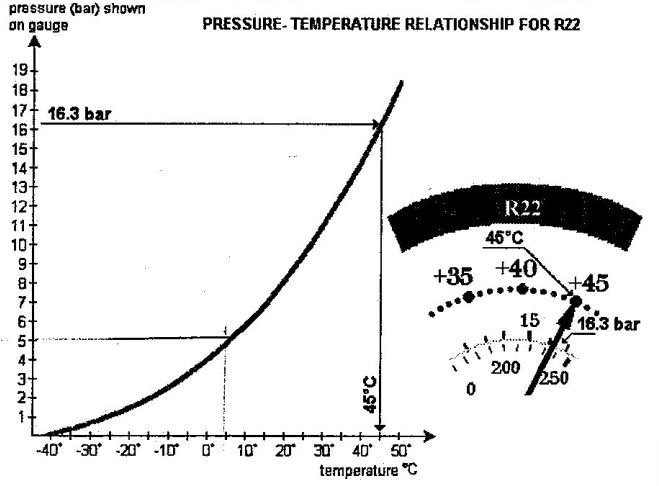

Let’s look at the pressure-temperature relationship diagram for R22;

This graph shows that at 16.3 bar, the condensation of R22 occurs at 45°C. The needle shows exactly 16.3 bar on the gauge at 45°C, precisely as it should from the graph.

What conclusion can you draw from this? First, the gauge shows the refrigerant’s pressure-temperature relationship.

The temperature shown on the gauge is that given by the pressure-temperature relationship of R22. It simply indicates that at 16.3 bar, the state change for R22 occurs at 45°C.

The pressure of the refrigerant at point A is 16.3 bar (the pressure measured by the HP gauge). On the other hand, the temperature is 75°C (measured with a thermometer)

Note that many refrigeration engineers use the symbol Tk when referring to the temperature at which condensation occurs. It means the same thing and is much shorter, so it’s a useful abbreviation to remember.

So, on the high-pressure side, the gauge indicates that the temperature at which the condensation takes place (Tk) is 45°C.

On the other hand, at point A, the vapour temperature is 75°C. That is, it’s greater than Tk by 75 – 45 = 30°C.

In the language used by refrigeration engineers, we say that the vapour at A is superheated. That is, its temperature is greater than Tk.

More precisely, we could say that since the vapour temperature at A is greater than Tk by 30°C. Therefore, it is superheated by or has a superheat of 30°C.

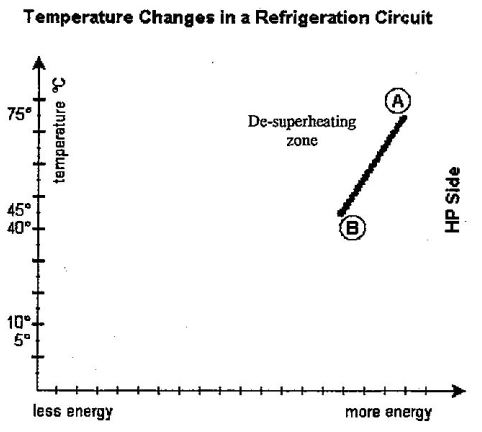

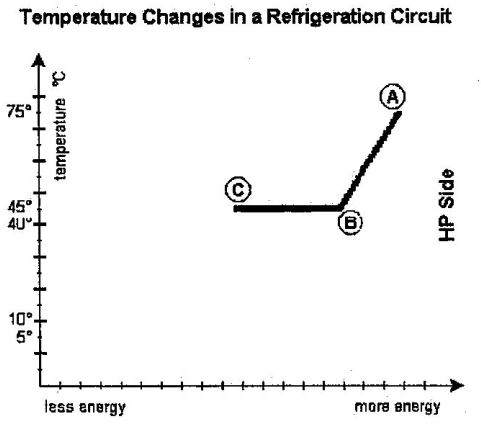

From point A to point B

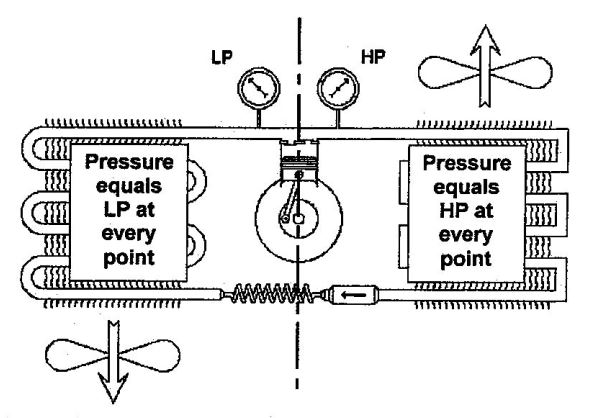

Before we continue, we must understand that in small refrigeration systems, like those installed in ‘comfort’ windows or split-system air conditioning units, only two pressures are present in the systems when they are in operation.

- High-pressure HP is the pressure at the outlet of the compressor to the inlet of the expansion device.

- Low-pressure LP is from the expansion device’s outlet up to the compressor’s inlet.

As the lengths of pipework are generally relatively short in comfort air conditioning, any pressure drops that these causes are negligible. It is because the pressure of refrigerant only falls by a minimal amount as it overcomes the resistance due to pipework.

The pressure at the condenser’s inlet is the same at the outlet. Therefore, the pressure on the HP gauge will be the same in the circuit between the compressor outlet and entry to the expansion device. Consequently, we can assume at every point in the circuit between the compressor outlet and the inlet to the expansion device, the pressure will be the same as the reading on the HP gauge.

For the same reasons, you should note the pressure of every point in the low-pressure circuit between the outlet from the expansion device to the inlet of the compressor will be the same as that read on the LP gauge.

But what happens between A and B?

Since the temperature of the air that passes over the condenser is less than that of the R22. The refrigerant will continue to cool.

The superheated R22 vapour will therefore cool until it reaches the change of state temperature, that is, the condensation temperature Tk. After that, the vapour will pass from 75°C to 45°C, from the superheated vapour temperature to the condensation temperature Tk.

The area of the condenser between A and B is known as the desuperheating zone. In this zone, the temperature of superheated vapour falls until it reaches condensation temperature.

As it passes through the desuperheating zone, the refrigerant releases its heat into the air. Do you think this heat is sensible, or is it latent?

As the temperature drop occurs as the refrigerant loses energy, we can sense it. Therefore, it must be sensible heat.

The gaseous R22 releases sensible heat as its temperature decreases.

Between A and B, the temperature of the superheated vapour gradually falls.

Its temperature will continue to fall until it reaches the condensation temperature.

As it enters the condenser, the gaseous superheat refrigerant crosses the desuperheating zone, bringing it to condensation temperature.

Point B

After the vapour has passed through the desuperheating zone, it reaches point B at exactly 45°C, the temperature at which condensation occurs.

But what would happen if this vapour at 16.3 bar and 45°C were to lose a little more energy (that is if it released a bit more heat)?

At point B in the condenser, the slightest loss of additional energy will immediately lead to condensation, and the first droplets of liquid R22 begin to appear.

Do you remember? The gauge told us that at 16.3 bar, the equivalent condensation temperature was 45°C! So point B is a theoretical point that marks the frontier between the desuperheating zone (in which there is 100% vapour) and the condensation zone (in which there is a mixture of liquid and vapour).

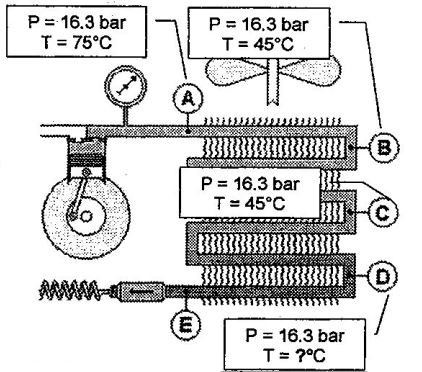

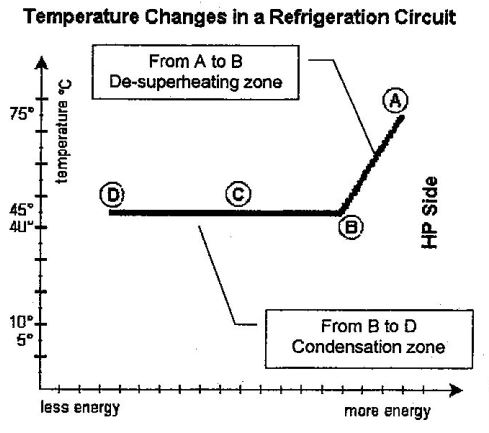

From Point B to Point C

From point B on, the refrigerant starts to condense. It changes its physical state, passing from a gaseous to a liquid state.

As cool air continually sweeps over the condenser. The refrigerant keeps losing energy, and condensation continues to take place. As it gradually passes through the condenser, the refrigerant continues to condense. And more and more liquid is produced (and, of course, less and less vapour remains).

The pressure is at a constant 16.3 bar. Therefore, all the heat released from the refrigerant will change the state (and is, therefore, latent heat).

Since We now find ourselves at the condensation step, the temperature of the liquid vapour mixture remains at a constant 45°C.

It is why a thermometer used to measure the temperature of an end piece at the middle part of the condenser, at point C, say, would read 45°C.

In refrigeration engineering terminology, this mixture of liquid and vapour is called saturated vapour. On the HP side, this mixture exists entirely at the condensation step. Therefore, this is the area where the pressure-temperature relationship for R22 indicated oh the gauge is valid (16.3 bar and 45°C)

From point C to point D

At point C, the refrigerant exists as a saturated vapour. It is a mixture of liquid and vapour at 45°C and 16.3 bar.

As it gradually passes towards point D, more and more condensation occurs. As a result, there is more and more liquid present and less and less vapour.

Note that after point B (where the first droplets of liquid appear), the refrigerant is in the form of a saturated vapour on the condensation step at 45°C.

The condensation zone ends at the precise point where the last molecule of the vapour condenses. No more vapour is left here, and 100% of the R22 is liquid.

The condensation zone ends at the precise point where the last molecule of the vapour condenses. No more vapour is left here, and 100% of the R22 is liquid.

The graph shows that during the whole period of the condensation step between B and D, the refrigerant loses energy in the form of latent heat.

Once more, let’s remind ourselves that the temperature remains constant for the condensation step at 45°C.

From point D to point E

At point D, the last molecule of refrigerant vapour has just condensed. There is, therefore, 100% of liquid R22 at 45°C and 16.3 bar.

But since cool air sweeps across the condenser. So it Continues to remove heat from the liquid R22.

Since the refrigerant is now 100% liquid, the heat removed can only be sensible heat, and its temperature will decrease.

At point E, which is at the condenser outlet, the liquid refrigerant will be below the condensation temperature T (say at 40°C). In refrigeration terminology, this is called sub-cooled liquid. It indicates that the liquid is at a temperature below that of the condensation step, i.e. below Tk.

The difference between condensation temperature and that of the liquid at the condenser outlet is called sub-cooling.

The zone between points D and E where this occurs is called the sub-cooling zone.

When the liquid is sub-cooled at the condenser outlet, there is certainly 100% liquid in the pipe. Sub-cooling is, therefore, a critical diagnostic indicator when there is a fault.

Now let’s look at what happens to the air at the condenser.

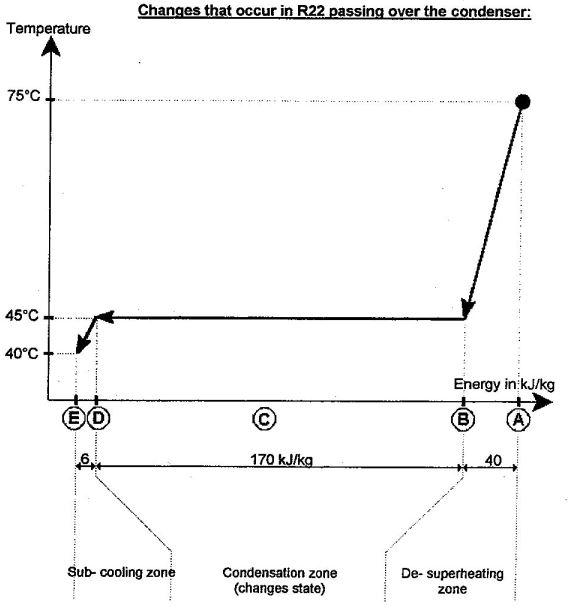

Firstly, the diagram should give you a fair idea of the different amounts of energy the refrigerant releases into the air as it passes over the condenser.

You can see that you must remove 40 kJ of energy to desuperheat 1 kg of R22 from 75 to 45°C (between A and B), but you only remove 6 kJ to sub-cool 1 kg of liquid by 5°C (between D and E). And remove 170kJ to condense 1 kg of refrigerant between B and D! The capacity of the condenser used for condensation alone (at constant temperature) represents close to 80% of its total capacity. It also means that nearly 80% of the condenser volume contains saturated vapour at 45°C.

These figures explain why we use the condensation temperature as the reference temperature for the HP side.

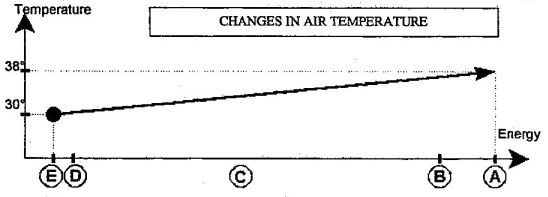

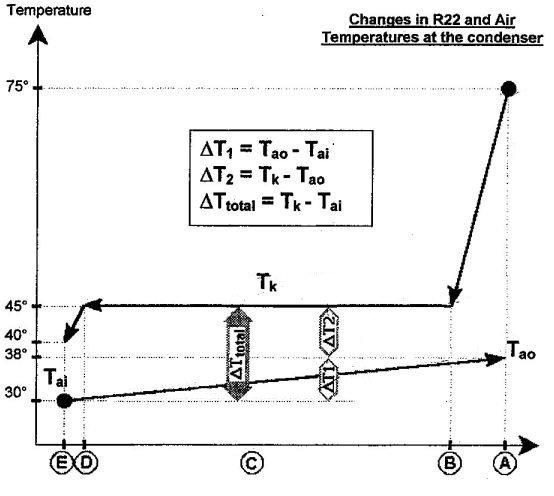

Now, if we examine the graph below, we’ll observe that the energy released by the refrigerant is absorbed entirely by the air that passes over the condenser.

The refrigerant releases most heat between B end D (the condensation zone); therefore, this is where we heat the air the most!

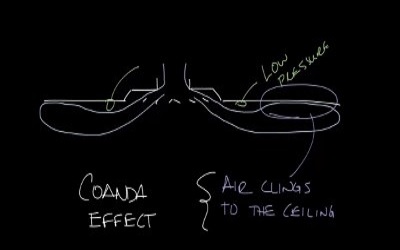

In this diagram for air, there isn’t a condensation step. Why is that?

That’s because there is no physical change of state of the air as it passes over the condenser, so only sensible heat is exchanged.

The temperature of the air gradually increases as it passes over the condenser, from 30°C as it enters the condenser to 38°C as it emerges from the condenser.

Note also that the coldest air enters the condenser from the side where point E is found and then passes towards point A. The air and the refrigerant are in a counter-current flow.

Counter-current flow significantly reduces the condenser size for a given cooling capacity.

We can also examine counter-current flow using the diagram. Note that the refrigerant enters at A and then emerges at E, whilst the air passes in the opposite direction. Finally, let’s look at the temperature difference involved.

The temperatures of interest to us are:

- Tk: Condensation Temperature of the refrigerant

- Tai: Temperature of air at the condenser inlet

- Tao: Temperature of air at the condenser outlet

Note that temperature differences represent by ΔT (delta T)

ΔT1 = Tao – Tai that is the air outlet temperature – the air inlet

temperature. This ΔT has a value here of 38 – 30 = 8K.

ΔT2 = Tk – Tao, the condensation temperature – the air outlet temperature. This ΔT has a value here of 45 – 38 = 7K.

ΔTtotal = Tk – Tai that, is the condensation temperature – the air inlet temperature. This ΔT has a value here of 45 – 30 = 15K.

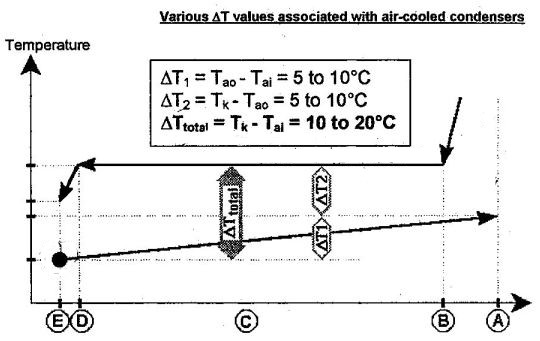

In general, for common comfort air conditioning systems, we find

- The temperature difference between the air inlet and the air outlet is between 5 and 10K.

- We also need a 5 and 10K temperature difference between the air outlet and condensation temperatures.

- Finally, the most interesting observation is the ΔTtotal, the temperature difference between the air inlet and the condensation temperature between 10 and 20°C.

Why should ΔTtotal be the most critical value?

Because measuring the external temperature is straightforward, we have an average ΔTtotal at the condenser of about 15K. So, if it’s 30°C outside, we can expect a condensation temperature (Tk) of about 45°C. So, when I connect the HP gauge, the condensation temperature should be about 45°C. If the gauge reading is much higher or lower than this, we immediately know there’s a problem!

In other words, the condensation pressure (the HP value) depends on the air temperature at the inlet to the condenser. For example, say it’s 30°C outside. And so 30°C at the condenser inlet. That’s why there is condensation at 30°C + 15K = 45°C.

When we put the gauge on the HP, the pressure should be 16.3 bar, and the corresponding indicated temperature on the gauge reads 45°C, as there is R22 in the system.

The HP value depends directly on the external temperature and the ΔTtotal value at the condenser. For example, in the above, when the external temperature is 25°C, the condensation occurs at 25°C + 15K = 40°C.

If it’s 40°C outside, the condensation occurs at 40°C + 15K = 55°C.

As the ΔTtotal characteristic of the condenser is 15K, the HP value will be as expected when factoring in the external temperature.

We’ve just seen the essentials of how an air-cooled condenser operates, and you should be able to understand everything discussed. The critical takeaway is that we need to know the ΔTtotal characteristic of all condensers installed, as each is different. In preventive maintenance and condition monitoring, we trend the ΔTtotal to give invaluable insight and pre-warning before problems occur.

Back to Basic!

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

Read more: What is coanda effect