Lessons learnt fan troubleshooting

Lessons learnt fan troubleshooting

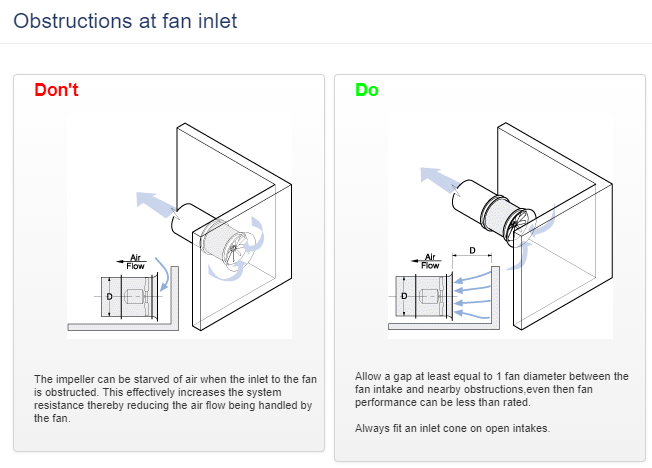

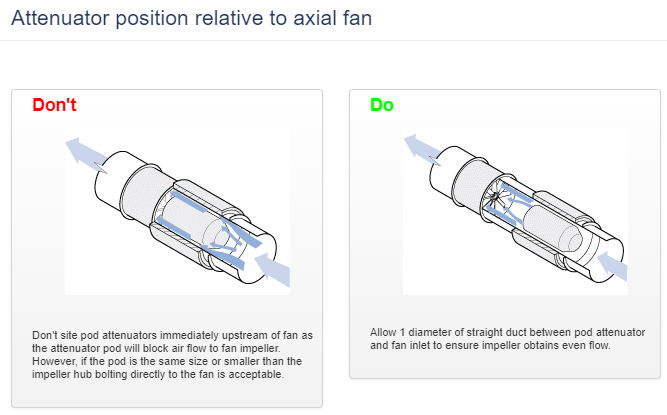

Here is a good resource to guide you on the best practice on the Do’s and Don’t of Fan Design and Installation. In fact when you speak to the engineers from Fantech, they will advise you to look through their guidelines. If a fan does not perform to design or specification, you will never be able to pin it onto the fan manufacturer because their performance curves are based on standard laboratory tests. When a fan problem occur, it’s almost always due to installation constraints and/or the fans are inappropriately installed.

I was asked to investigate into some return fans that were only delivering 70% of design capacities.

Problems identified

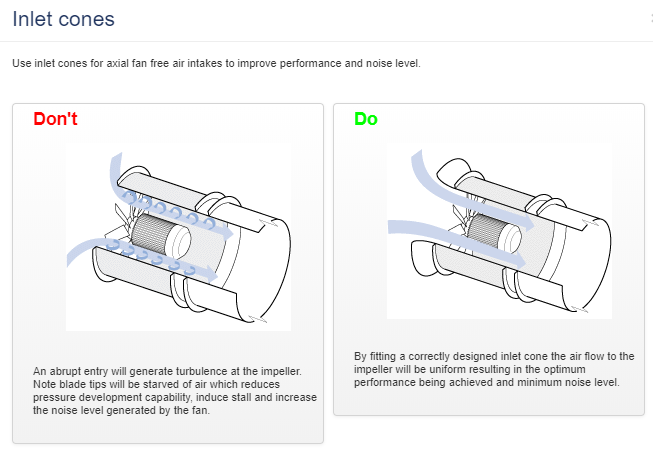

Problem 1: The fans inlet to the wall were less than one fan diameter clearance. If only one were to study Fantech Don’t/ Do recommendations this may not be a problem

Problem 2: The attenuators installed which pods were larger than the fan hub diameter. If only one were to study Fantech Don’t/ Do recommendations this may not be a problem.

Attenuators has its place and application, but it should not be used for the very first instance, it’s not the Holy Grail of noise control. To my amazement, I see it all the time that silencers as well as internal linings being specified for kitchen exhaust ducts. I do wondered how are we suppose to clean these kitchen exhaust ducts.

Problem 3: The were no inlet cones installed. If only one were to study Fantech Don’t/ Do recommendations this may not be a problem

The million dollar question was, how much improvement will we get if we were to rectify the problems identified?

There is no telling how much the improvements there will be until it’s done. That is the reason why it’s best to get it right the first time. In fact we were prepared to scrap the fans but I was cautiously optimistic that we can get within the design air flow rate if were were to make all the required changes. Was I confident? Not really.

My lengthy conversation with the engineers from Fantech provided me with some guidance of about 5- 10% improvement by removing the attenuators, and perhaps another 5% after installing the inlet cones … perhaps more!

We went ahead to rectify the problems, here are the improvements results;

| Corrective Action | Improvement | Percent improved |

|---|---|---|

| Before Corrective Works | 70% of design | – |

| Removing Attenuators* | 83% of design | improved ~ 18% |

| Adding Inlet Cones | 98% of design | Improved by another ~ 18% |

*after removing the attenuators, we have more than one fan diameter between the wall and fan inlet cone.

I knew that we need to install inlet cones for open ended fans, but do not know for sure the possible quantum, a whopping 18% improvement! Now I know.

The next time yo install a free field open ended fan, make sure you install the appropriate inlet cones.

Image source: fantech.com.au/Content.aspx?ContentID=L5

Related

Read more: Fan wall

Read more: How to verify the percentage of outside air in an enclosure

Read more: BCA Part J5 Air-conditioning system control

Read more: Microbial Induced Corrosion (MIC) in Pipes

Read more: Is your kitchen exhaust system a fire hazard

Read more: What is coanda effect